I couldn’t put it off any longer. The timing belt on my MkV Gold just had to be replaced. As it happens, this was nothing like as bad as I feared and certainly easier than on my Fiesta.

The first task – and the most demanding – was to remove the crankshaft pulley in order to get the timing belt cover off. Of course, as usual this is tightened to a ridiculous torque. Surely there must be a better way of solving the simple problem of holding a pulley onto a shaft.

On my Fiesta this is a normal hex bolt which really requires an impact socket to get it off safely but VW have at least thought about this and the bolt head is a strange design which effectively the inverse of a normal socket. Clearly this gives a lot more contact surface and should ensure that the bolt head doesn’t get rounded off.

A quick check showed that it needed a 21mm socket but this was a little bit loose on this strange bolt head. When this sort of thing happens I like to check to see if any of my imperial sockets will give a better fit and – top tip coming up – it turns out that a 7/16 Whitworth (which is actually 20.83 mm) fits perfectly.

I now deployed my home made clamping bar taking great care to adjust the bolts which engaged with the pulley and attached my breaker bar to the socket. The photo below shows this. Note the cardboard to protect the drive shaft.

Getting enough force onto the end of the breaker bar was going to be an issue, so I used the old scheme of putting my trolley jack under the end and slowly raising it. This did the trick and I was soon able to proceed to the next stage.

The next step was to remove the offside engine mount so I carefully supported that end of the engine on wooden blocks and after shifting things like the water expansion tank out of the way this wasn’t too tricky.

The Golf has a rather strange arrangement whereby there are two timing belts. One runs from the crankshaft to the rear camshaft and the second smaller one joint the two camshafts together. I haven’t seen anywhere an explanation of why this is a good idea.

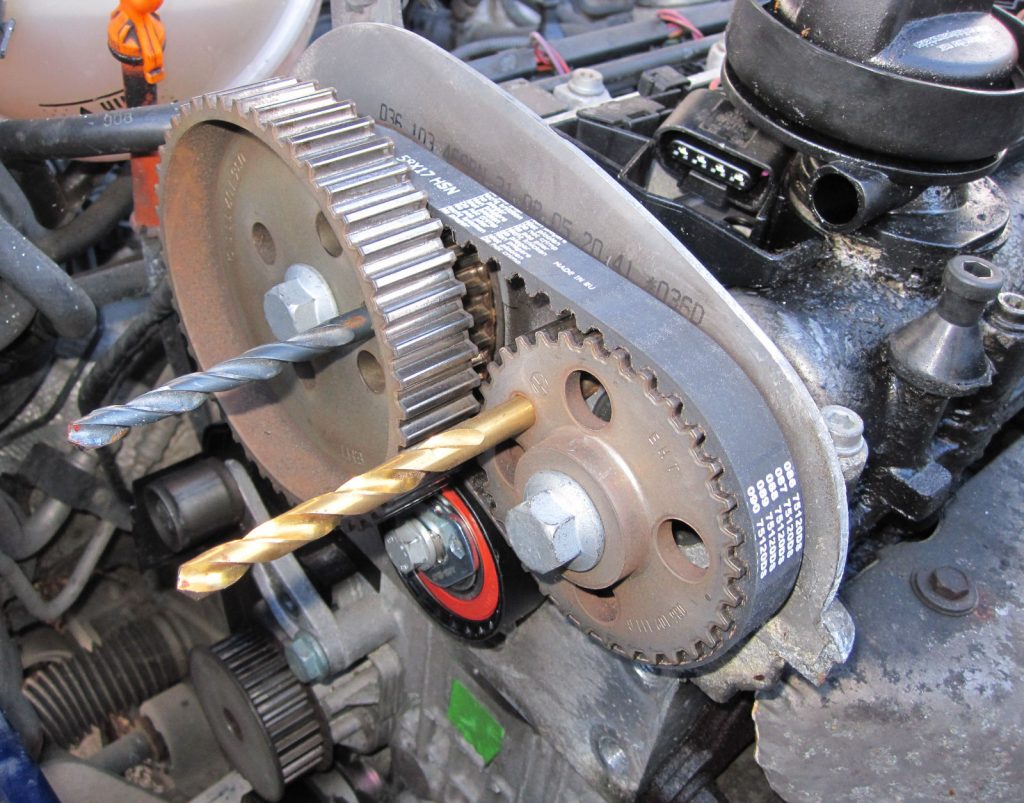

VW have a very simple scheme to align the camshafts which consists of holes in the cam pulleys and corresponding holes in the engine block. You can buy an expensive tool to fit into these holes, but comments on various forums suggested that it is just as easy to use a couple of drills and I found that this was the case. The one thing you have to watch is that you don’t cut yourself on the exposed sharp ends. I guess you could protect these with some tape. I didn’t bother and got away with it.

I decided to take the opportunity to replace all of the idler and tension pulleys together with the water pump as this seemed to be often recommended and I was able to buy a combined kit with these parts and the two timing belts. The photo below shows the end of the engine with all these items for the main belt removed. The tensioner at the top is for the smaller belt. The strange bolt for the cam pulley is just visible at the bottom.

It was then just a case of fitting all the new items and correctly setting the tensioners.

My Haynes manual was keen to stress that a number of bolts, particularly in the engine mount needed to be replaced with new ones and then angle tightened. I understand that these are special bolts which rely on the metal going beyond its elastic limit when tightened but that this can only be done once.

Many other commentators were of the view that this was a council of perfection and that the special bolt tightening scheme only made sense in the factory. In the end I decided to take a chance and simply re-used the old bolts tightened to the specified torque without any angle tightening. In the case of the crankshaft bolt I took the precaution of adding a spot of Loctite and a bit of wire which would break if the bolt started to come loose.

With everything re-assembled and the alignment checked after hand cranking the engine a couple of revs I started it up and to my great relief it ran just fine.

Update – October

The car has now done a couple of thousand miles with the new belts. I checked the bolts regularly the first few hundred miles and nothing seems to have come loose. I seem to have got away with re-using the bolts, but of course I might have been lucky.