Today I fitted my new polyurethane suspension bushes and it was ridiculously easy. Just as in the YouTube videos, all I had to do was bash them in with a lump hammer using a lump of wood to add some protection. Then the rubber mallet to drive home the steel tube in the centre.

The supplied grease made this even easier and I found that I could push the bushes about 20% of the way in by hand! No more rubber bushes for me.

It was then time to tackle the rusty brake pipe. I experimented first with my new brake pipe flaring tool and it was very easy to use. Essentially, you push the brake pipe in against a stop, tighten the clamp, remove the stop and then screw in the flaring bit. The only tricky thing is remembering to put the required fitting onto the pipe before you flare it!

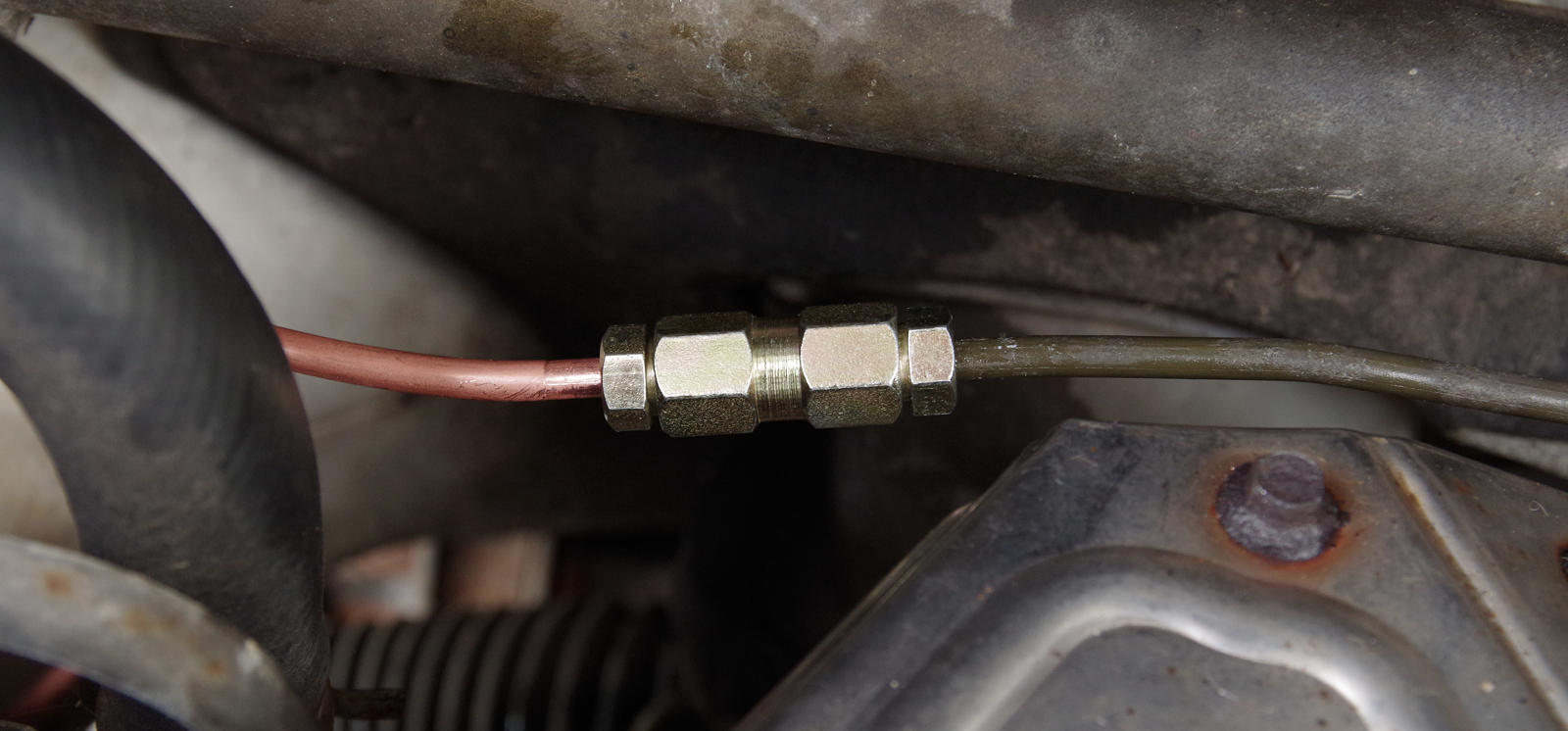

Since only the part of the pipe in the wheel arch was rusty I elected to cut the pipe where it passed behind the engine and use a joining piece to add a replacement end.

Bending the new pipe to the same shape as the old one was easy as it is very thin and flexible.

Once the new section was fitted it was just a case of bleeding the brake with my splendid pressure bleeding kit.